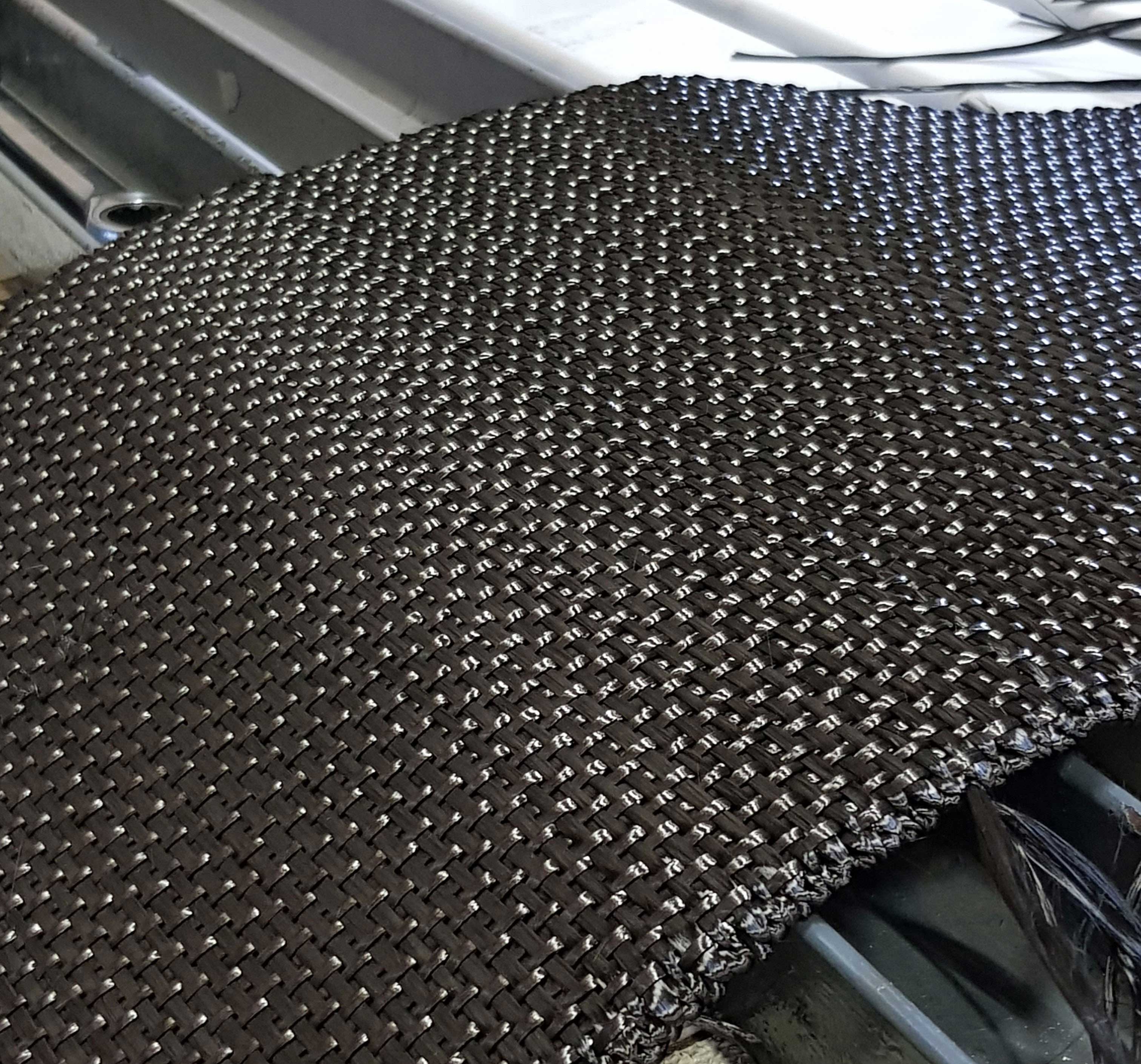

3 Boyutlu(3D) dokuma; belirli geometri ve iç desen yapısında, 3 eksen elyaflardan oluşan, özel bir dokuma makinesi ile üretilebilen ön şekil üretim teknolojisidir.

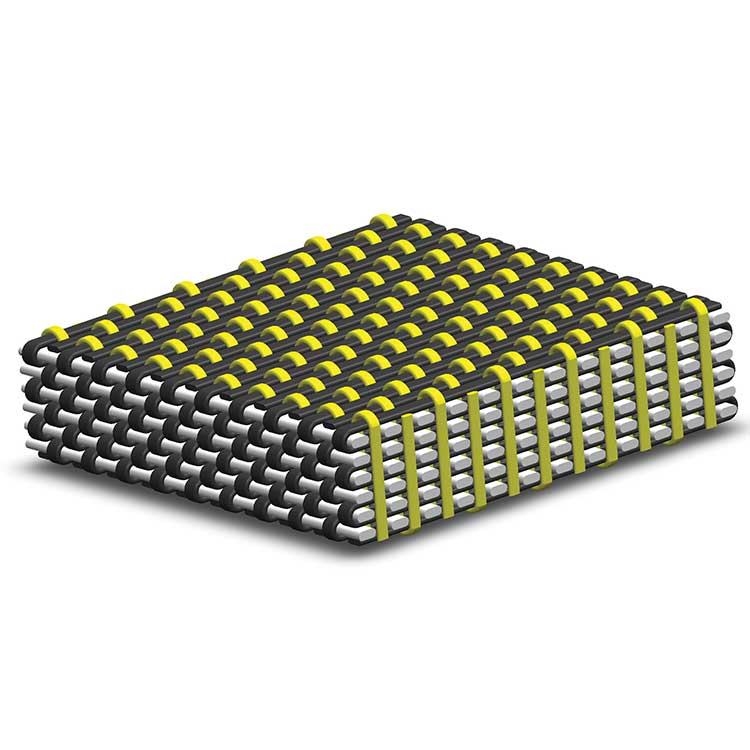

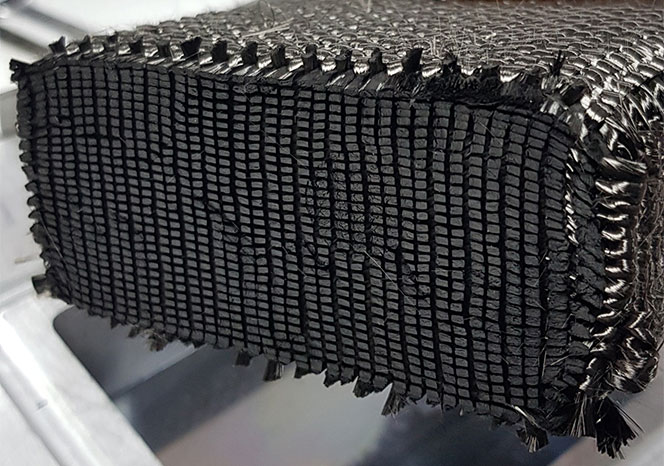

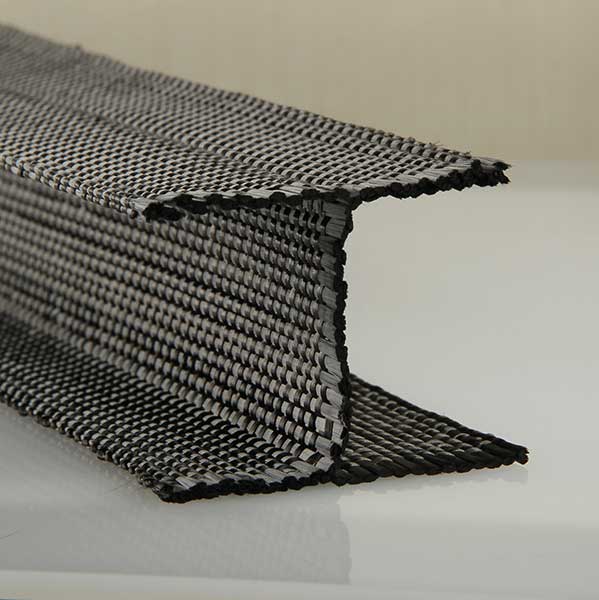

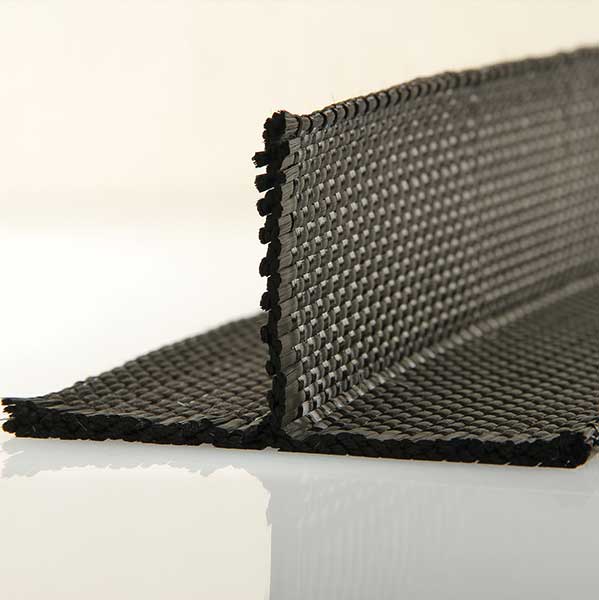

Geleneksel dokuma üretim yöntemlerinde bulunan atkı ve çözgü elyaflarına ek olarak Z ekseninde de elyaf dokuma teknolojisi sayesinde dokunmuş son ürün belirli bir kalınlığa sahip olmaktadır. 3D dokuma yöntemi ile ön şekil üretimi için özel tasarlanmış makine ve programlar kullanılmaktadır. 3 boyutlu dokuma teknolojisinde karbon, cam ve aramid gibi çeşitli elyaflar kullanılabilir.

Son ürünün kullanılacağı yere bağlı olarak 3B dokuma yöntemiyle sayısız farklı çeşitte desen dokuma yapısı oluşturulabilmektedir. 3B dokuma yönteminde en çok kullanılan desen tasarımları ortogonal, katlar arası açılı kilitli ve kalınlık boyunca açılı kilitli desen tasarımıdır. Desen tipine ek olarak kullanılan elyaf türü de 3B dokunmuş ön şekillerin mekanik, termal, fiziksel özelliklerini ve reçine sistemi enjeksiyon işlemini doğrudan etkilemektedir.

Kompozit takviye ve matris olarak adlandırılan iki veya daha fazla malzemenin birleşiminden üretilir. Bu malzemelerin mekanik, termal ve fiziksel özellikleri son ürünün özelliklerinin belirlenmesinde etkilidir. Laminasyon, pultrüzyon, serme, elyaf yerleştirme ve 3d dokuma gibi farklı kompozit üretim yöntemleri vardır.

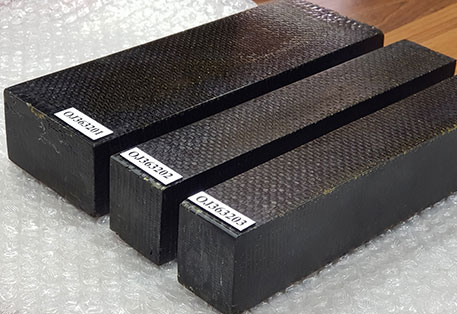

3D Dokunmuş Kompozitler ise 3D Dokunmuş ön şekillere çeşitli yöntemler kullanılarak reçine transferi yapılması ile üretilmektedir. Ön şeklin dokuma desen tasarımı, kullanılan elyaf çeşidi, eksenel elyaf oranları, ön şekil yoğunluğu, reçine sisteminin özellikleri ve reçine transfer prosesi son ürünün özelliklerinin belirlenmesinde etkilidir. Bu parametrelerin değişikliği ile istenilen özelliklerde kompozitlerin üretilmesi mümkündür.

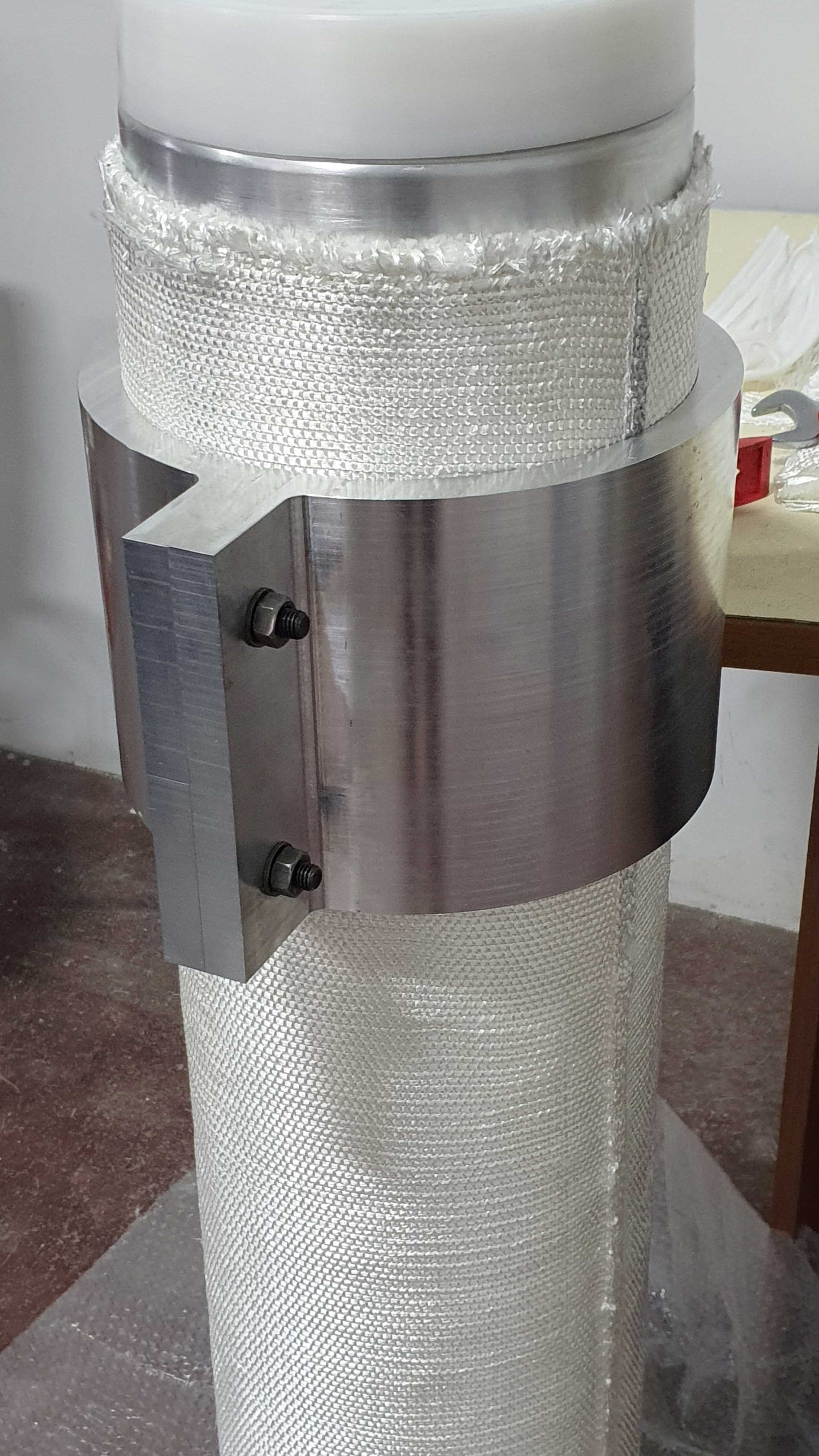

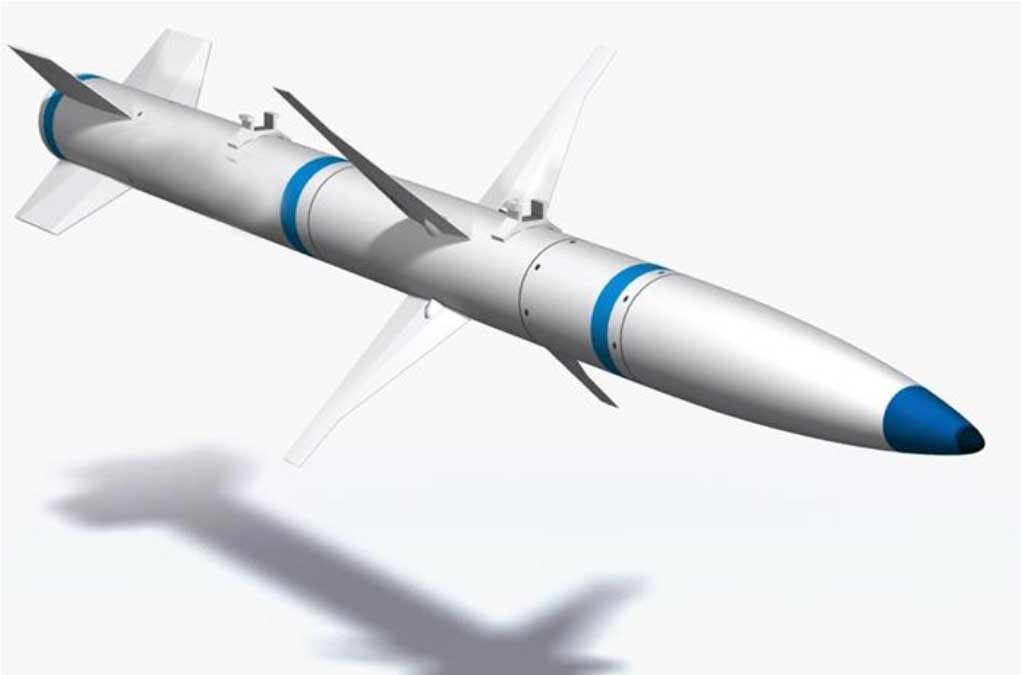

Yanma odası yalıtım malzemesi, motor yalıtımı, nozul, refrakter, radom ve çatışma perdesi (bulkhead) olarak kullanılır.

Türbin motor fan bıçakları, fan motoru kasası, çıkış kılavuz kanadı (OGVs), karbon fren, iniş takımı, uçak gövdesinde T-Pi-H vb. taşıyıcı profil olarak kullanılır.

Jiroskop volan (Gyroscope flywheel), tepki çarkı (reaction wheel), güç depolama cihazları (power-storage devices) olarak kullanılır.

Yüksek sıcaklık dayanımlı ve üstün mekanik özellikli termal koruma sistemleri olarak kullanılır.

Hafif ve dayanıklı mayın zırhı olarak kullanılır.

Düşük akustik gürültüye ve yüksek mekanik dayanıma sahip pervane kanadı olarak kullanılır.